During the rice milling process, a lot of broken rice is generated, due the outlook and taste reason, the price of broken rice is relatively lower than whole rice grains.

In the process of human development, the nutrients intake demand is getting higher and higher, the natural rice nutrients are hard to reach human body intake demand, such as Vitamin A, C, D, E, minerals, etc. Due to these reasons, the artificial nutrient fortified rice production line was researched and manufactured. This production line can pulverize borken rice, and then reshape rice grains by extrusion technology. Moreover, during the extrusion process, the artificial rice production line can produce various kinds of nutritional rice, which based on different people demands and different formulas. Such as the golden rice, sweet potato rice, gingsen rice, pumpkin rice, and pea rice, and so on. In addition, this artificial rice production line can be used for producing the instant rice as well.

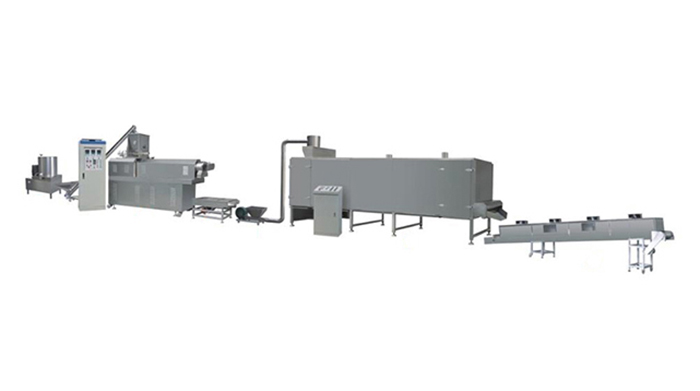

This artificial rice production line is with advantages of high automation degree, simple operation, low power consumption and environmental friendly.

First, putting all the flour form raw materials, additives into mixer, and mixing with drinking water, then mixtures be transported by screw conveyor to extruder feeder. The feeder feeds raw materials into extruder’s extrusion barrel evenly. In the extruder, the raw material is matured by shearing action between barrel and screws, and also the heat action in barrel. Then the dies forms raw materials into rice shape, and the cutting system cuts the rice with different sizes, then the rice falling down to vibrating sifter, the vibrating sifter generates vibration to avoid rice stick together, and helps to remove the surface moisture of rice. After that, the air conveyor transports the artificial rice to Mulity-layer dryer, to dry the extra moisture of artificial rice, which used to ensure product shelf life. After drying, the artificial rice will go through a cooling conveyor, to cool down artificial rice temperature to ambient temperature. At the same time, the artificial rice product will be transferred to the packing machine, to get the final artificial rice product ready for sale.