Industry news

Twin-screw extruders and pellet machine differ significantly in fish feed production, primarily in terms of process principles, finished product characteristics, production efficiency and cost, and applicable scenarios:

I. Core Process Differences

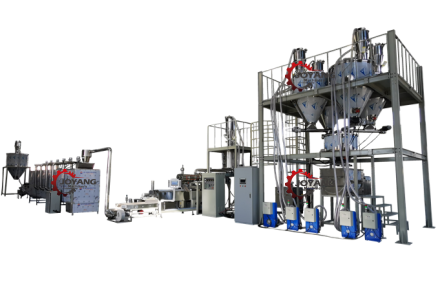

. Extruder (Twin-Screw)

High-Temperature and High-Pressure Extrusion: The raw materials are steam-conditioned (moisture content 25%-35%) and then instantaneously expanded under high temperatures and pressures of 110-200°C, forming a porous structure.

Screw Structure: The twin-screw extruder achieves strong shearing through frictional extrusion, enabling precise density control (for buoyant/sinking feeds).

. Pellet Mill

Physical Pressing: The raw materials are steam-conditioned at approximately 80°C (moisture content 17%) and then extruded through a ring die by rollers, eliminating the need for expansion.

Simple Structure: Single-stage extrusion, relying primarily on mechanical pressure to form dense pellets.

II. Comparison of Feed Characteristics

Stability in Water:

Extruder: Remains in place for 12-6 hours, reducing water pollution

Pellet machine: Easy to disperse

Digestibility

Extruder: 90% starch gelatinization, high nutrient absorption

Pellet machine: Gelatinization approximately 60%, low digestibility

Density Control

Extruder: Flexible production of floating or sinking feeds

Pellet machine: Can only produce sinking feeds

III. Production Efficiency and Cost

Twin Screw Extruder Advantages

High Capacity: Twin-screw extruders can produce 2-8 tons per hour, suitable for large-scale continuous production.

Expandable Functions: Capable of processing high-fat formulas (fat addition ≤ 30%).

Pellet Machine Advantages

Low Investment: Equipment costs are only 1/3-1/2 of those of an extruder.

Low Energy Consumption: No high-temperature or high-pressure processes, reducing power consumption by over 30%.

IV. Recommended Application Scenarios

Choose an extruder:

Requires floating feed (such as sea bass and trout), a high-fat formula, or large-scale production (annual production ≥ 10,000 tons).

Choose a pellet machine:

Small farms, sinking feed (such as carp and shrimp), or budget constraints.