Microwave machine's benefits for tea leaf fixation are primarily reflected in the following aspects:

1. Fast and Efficient Fixation

Microwave fixation uses high-frequency electromagnetic waves (commonly 2450MHz ) to induce rapid motion of polar molecules within the tea leaves, generating heat energy. This simultaneously raises the temperature inside and outside the tea leaves to above 80°C. Fixation takes only 1-2 minutes, 80% less than traditional stir fixation.

2. Quality Improvement

Color Retention: Rapidly inactivates polyphenol oxidase activity, preventing oxidation of tea polyphenols and preserving the tea's vibrant green color.

Aroma Development: Volatilizes the odor of fresh leaves, promotes the formation of tea aroma compounds, and preserves more active ingredients such as amino acids.

Uniformity: Penetrating heating prevents burning and debris, resulting in superior heating uniformity compared to traditional drum fixation.

3. Energy Saving and Environmental Protection

Low Energy Consumption: The electricity cost per kilogram of fresh leaves is less than 0.3 yuan (at 1 yuan per kilowatt-hour).

Pollution-Free: No open flames or smoke emissions, meeting green production requirements.

4. Versatility

Moisture Control: Withering simultaneously evaporates approximately 10% of the moisture, facilitating subsequent rolling.

Sterilization and Aging: Microwaves also sterilize, reducing the bitterness of summer and autumn teas.

5. Industrial Adaptability

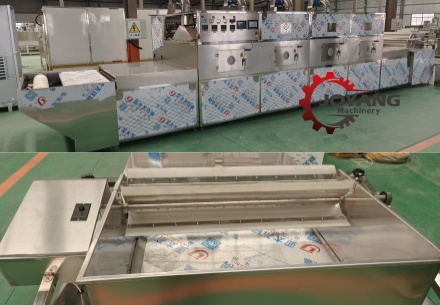

Automated Operation: A PLC touchscreen controls temperature (80-120°C) and conveyor speed can be adjusted, allowing one or two people to complete continuous operations.

Wide Application: In addition to tea, microwave technology can also be used to wither agricultural products such as chrysanthemums and honeysuckle.

Compared to traditional withering methods, microwave technology significantly improves efficiency and quality consistency, becoming a key driver of modern tea processing.