Shandong Joyang Machinery Co., Ltd. has been committed to the research and development, production, sales and service of puffed food equipment, pet food equipment, aquatic feed equipment and soybean tissue protein equipment. The two models currently sold by our company are single screw extruder and twin screw extruder.

Below, for the twin-screw extrusion technology, we will make the following explanations of technical principles:

The technical feature of the twin-screw extruder is the use of twin-screw extrusion technology. It is the most popular and effective technology in pet food, aquatic feed, puffed snacks and soy tissue protein production industries.

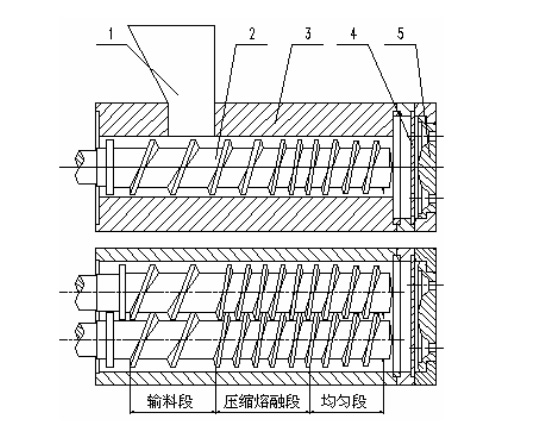

Twin-screw extruders adopt a couple of paralleled and joggled screws to push raw materials forward. The screw is divided into three parts: conveying segment, fusion segment and homogeneous segment. In conveying segment, materials are fed into barrel through hopper. Through screws rotation, materials go forward along screw channel, and be compacted gradually. When materials come into fusion segment, because of screw’s structure change, pressure is higher. Because the forceful mixing and shear force to produce temperature, assisted by outside heating, materials begin fusing, until fuses completely.

Through screw channel interspace decreases gradually, materials’ temperature and pressure is higher and higher. It cooks materials, to make materials’starch gelatinize. In the process, fat and protein have physical and chemical reactions. In homogeneous segment, materials go through spreader plate to die mould. Normally, the pressure is 3-6MPa (according to different extrusion requirement), the temperature is 150-200℃. In airtight barrels, this pressure exceeds saturated vapor pressure (at this temperature), the moisture won’t be evaporated fleetly. When materials go through die mould holes, the pressure reduces fleetly, free moisture is evaporated fleetly. Materials expand, moisture coming from materials fleetly, product temperature is cooled to about 80℃ fast,materials are shaped into their settled shapes.

With advanced technology and professional services, Shandong Joyang Machinery Co., Ltd. will become your professional technology and equipment supplier!