Last year, our Mali customer purchased a 1 ton/h wet extrusion aquatic feed production line. On December 7th, our company dispatch engineer to the customer's workshop to provide installation and commissioning guidance. This production line includes raw material processing, mixing, extrusion, drying, flavoring, cooling, packaging.

Engineers conduct on-site surveying and mapping based on the specific conditions of the customer's workshop to determine the installation location of the production line (the production line can be installed in an "I" shape, "L" shape, or "U" shape); installed boilers and steam pipes to ensure the stability of steam pressure and provide enough steam for the conditioner, extruder, and dryer; connect the power supply to each machine, etc.

Smoothly installation process is also inseparable from the customer's adequate preparation, such as electricity, cooling water, packaging bags, labor, etc.

After installation, our engineers will commissioning the production line according to the user’s raw materials and conduct systematic training for the user. Systematic training ensures that the user can independently operate the machine, clean the machine, repair the machine, and so on.

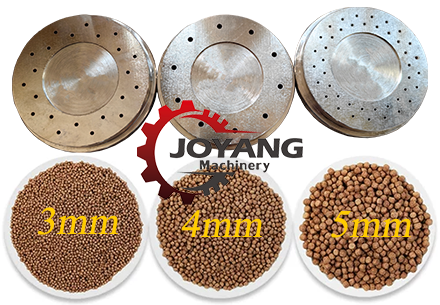

In order to meet customers different requirements, our aquatic feed production line can produce aquatic feed in different sizes from 1.5mm to 14mm, with capacity ranging from 150 kg/h to 5 ton/h, etc. According to the specific requirements of customers, we can provide various production line solutions and provide customers with professional customized services. Welcome to inquiry.